Machines and devices don't start with screws. They start with a question.

“Can it be automated?” – this sentence uttered by our Clients starts most of the projects at NEOTECH.

The reasons for automation are varied. A manufacturer of sensors, engines, bottles or lollipops wants to speed up the assembly or packaging process, better control the quality of the product, increase efficiency or simply gain an advantage over the competition. Then a team of engineers steps in and… brainstorming begins.

Imagine a robot that grabs a small element in a split second, does something with it, carries it and puts it on a conveyor belt. It does this thousands of times a day, without getting tired, without whining, always with the same precision. Now try to imagine how such a machine is even created. No, not in a magic factory somewhere in Silicon Valley. Only here – in Białystok, Poland, step by step, by people who turn ideas into technical drawings and technical drawings into steel and movement.

Step 1: Understand humans. Then machines.

Contrary to appearances, creating a machine is largely detective work. We have to obtain detailed information from the customer, find out what they really need. Sometimes it is not the customer themselves who are the source of information, but their production line – the processes before and after the automated fragment. Engineers thoroughly analyze the process, look at how people and other machines work, what can be accelerated, simplified, modified or… eliminated. They add specific requirements to this, starting from external dimensions and type of power supply, through integration with existing data acquisition systems, to the choice of whether the machine should have legs or wheels.

From these observations, something much more exciting than a dry table is born – the concept of the machine.

Complete winding and insulating production system for SMD transformer production.

Designed and constructed by NEOTECH.

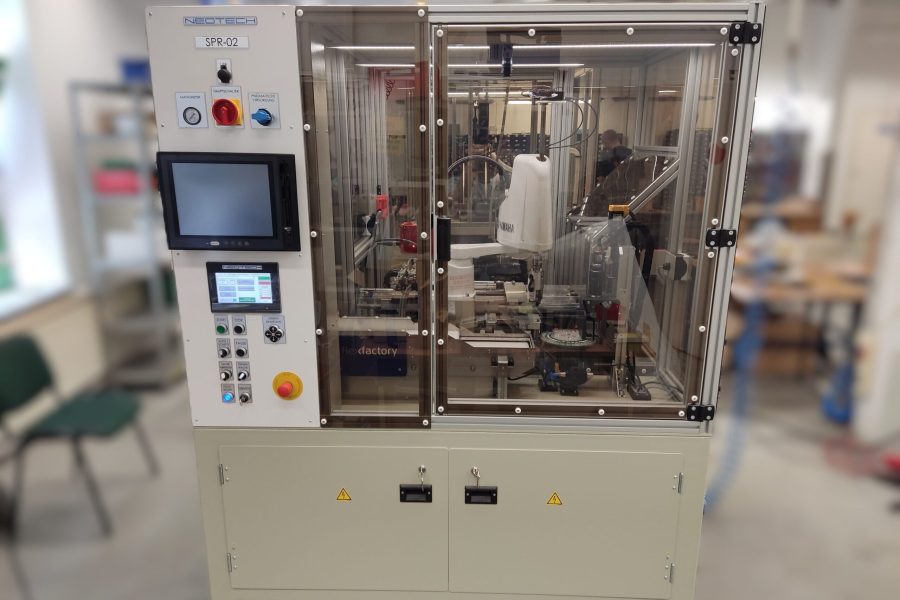

SPR-02 ferrite core inspection and packaging machine. Universal equipment enables quick changeovers. Designed and constructed by NEOTECH.

Step 2: Brains vs. CAD

Once you know what the machine is supposed to do, it’s time to put the idea on the screen. A virtual model is created in 3D design programs. Each element of the machine must fit to the tenth of a millimeter, and this is ensured at this stage.

A mechanical design is created, electrical, pneumatic or hydraulic documentation is created, a list of components to buy, a list of components to make… The Supply Department starts ordering various parts, and engineers and designers prepare everything so that the machine can be assembled right away.

We perform 3D CAD modeling mainly in the DS SolidWorks environment.

Step 3: Welding machines, wrenches, screws and cables

Time for physical birth. In the mechanical and automation design workshops, our experienced employees assemble the machine from prepared elements. This is where the real life of the machine begins: the robot is mounted on a frame, engines, actuators and guides are screwed on, electrical cabinets and equipment units are assembled. Cables are pulled through like the human nervous system. The world of metal and electricity interlocks. Every detail must be placed with surgical precision, because the smallest error can then even paralyze the entire process.

At the same time, automation engineers and programmers prepare programs for the machine. How does the machine know where the robot should go, which orientation of the element is correct, what it should move and which actuator is responsible for what? Well, from a very detailed program!

SPR-02 machine during assembly. Visible are the frame with built-in electrical cabinets, vibratory feeder and SCARA robot arm by YAMAHA.

Step 4: NASA-like testing

Before the machine leaves the hall, it undergoes a series of tests that can be compared to the checks before sending a rocket into space. Everything is checked: sensors, positioning, mechanics, emergency reactions, touch panels.

One click of a button can start a sequence of a dozen actuators, engines and cameras. Everything must be synchronized. The final test before leaving the assembly hall is the trial production batches. Perhaps the actuator closes a fraction of a second too late or the gripper goes down a sheet of paper too low? Do the cycles performed really result in compatible products? Now is the best time to refine the program and make corrections. If the tests pass – it’s time for the final stage.

Step 5: Rebirth of the machine in the factory

The machine arrives at the customer’s plant. If it was disassembled or immobilized for transport, it is now resuscitated. It is connected to electricity, air, and sometimes also to systems cooperating in the production line. It undergoes the so-called final start-up, calibration and tests “live”. It cannot be done without performing trial production cycles. Of course, the customer is present and decides on the acceptance of the machine.

At the end, the technologists, the maintenance department or operators receive instructions, are thoroughly trained and receive the “keys” to the latest acquisition, which is another innovative NEOTECH machine.

An assembly machine for automotive components during the last tests of transferring plastic parts. Equipped with a 5-axis KUKA robot.

Machines as a work of art

In the process of creating industrial machines, we are fascinated by the combination of abstract thinking – necessary for every engineer, with real problems and solutions. From an idea on a napkin, through computer visualization, to a system that performs thousands of operations every day – a machine is the result of engineering precision and imagination. And although each of them looks different, they have one thing in common: they are created to meet the needs of customer companies, but also – above all – people.

At NEOTECH, we show that automation is not the future. It is the present. And our best machines are created not in factories, but in the minds of people who can understand both man and metal.

🛠️ See sample machines made by NEOTECH:

Trust our experience - build your next machine with NEOTECH!

We invite you to contact us:

And to follow NEOTECH on social media: